Automatic CNC 2D Wire Bending Forming Machine with Welding

The Automatic CNC 2D Wire Bending Forming Machine with Welding offers precision bending and welding. Efficient for wire product manufacturing.

Product Description

2D Wire Bendin Machine

Introduction of Automatic CNC 2D Wire Bending Forming Machine with Welding

The Automatic CNC 2D Wire Bending Forming Machine with Welding combines bending and welding. Precise and efficient for wire product fabrication.

Product Specification of Automatic CNC 2D Wire Bending Forming Machine with Welding

| Name | Automatic CNC 2D Wire Bending Forming Machine with Welding |

| Electrical voltage | 3Phases 4 wires+ground wire |

| Number of straightening wheels | 28 groups |

| Bending molds | 62Made of SKD11/51 with hardness 62 |

| Bending precision | ±0.5 ° |

| Wire Feeding Precision | ±0.5 ° |

| Applicable wire | Round wire, flat wire, square wire |

| Production Speed | 15-20 pcs/min (take square 200*200mm as an example) |

Feature and Application of Automatic CNC 2D Wire Bending Forming Machine with Welding

The Automatic CNC 2D Wire Bending Forming Machine with Welding features high precision bending and reliable welding. It is controlled by CNC for accurate shaping. Can handle various wire materials. Applications include manufacturing wire frames for furniture, automotive parts, and industrial components. It increases production efficiency and quality, reducing labor costs. Ideal for businesses seeking automated wire processing solutions.

Instructions:

Instructions for Automatic CNC 2D Wire Bending Forming Machine with Welding: Load wire. Set parameters on CNC panel. Start machine to bend and weld wires. Monitor process. After use, clean and maintain regularly for optimal performance and longevity.

How To Use:

Instructions for Automatic CNC 2D Wire Bending Forming Machine with Welding:

Step 1: Preparation Inspect the machine to ensure all parts are in good condition. Prepare the wire of appropriate size and material.

Step 2: Loading Wire Carefully insert the wire into the machine's feeding mechanism. Adjust the tension as needed.

Step 3: Setting Parameters Use the CNC control panel to input the desired bending angles, shapes, and welding settings. Ensure accuracy.

Step 4: Starting the Process Press the start button to initiate the bending and forming process. The machine will automatically bend the wire according to the preset parameters.

Step 5: Welding Once the wire is bent into the desired shape, the welding function will kick in. Monitor the welding process to ensure a strong bond. **Step 6: Completion and Cleanup** After the process is complete, remove the finished product. Clean the machine to remove any wire debris or residue. Perform regular maintenance for optimal performance.

To adjust the bending angle and shape of the machine, you can follow these steps:

For adjusting bending angle:

1.Access the control panel of the Automatic CNC 2D Wire Bending Forming Machine with Welding.

2.Look for the parameter settings related to bending angles.

3.Enter the desired angle value using the input interface. This could be a numeric keypad or a slider control depending on the machine's design.

4.After entering the value, confirm the setting. Some machines may require you to press an “enter” or “confirm” button.

5.Run a test bend with a small piece of wire to check if the angle is as desired. If not, repeat the process and make further adjustments until the correct angle is achieved.

For adjusting shape:

1.On the control panel, find the settings for shape parameters. This might include options for different geometric shapes like circles, rectangles, or custom shapes.

2.Select the desired shape from the available options. If custom shapes are possible, you may need to input specific coordinates or use a graphical interface to draw the shape.

3.Adjust any additional parameters related to the shape, such as length, width, or radius.

4. As with adjusting the angle, run a test with a small amount of wire to ensure the shape is correct. Make any necessary adjustments until the desired shape is obtained.

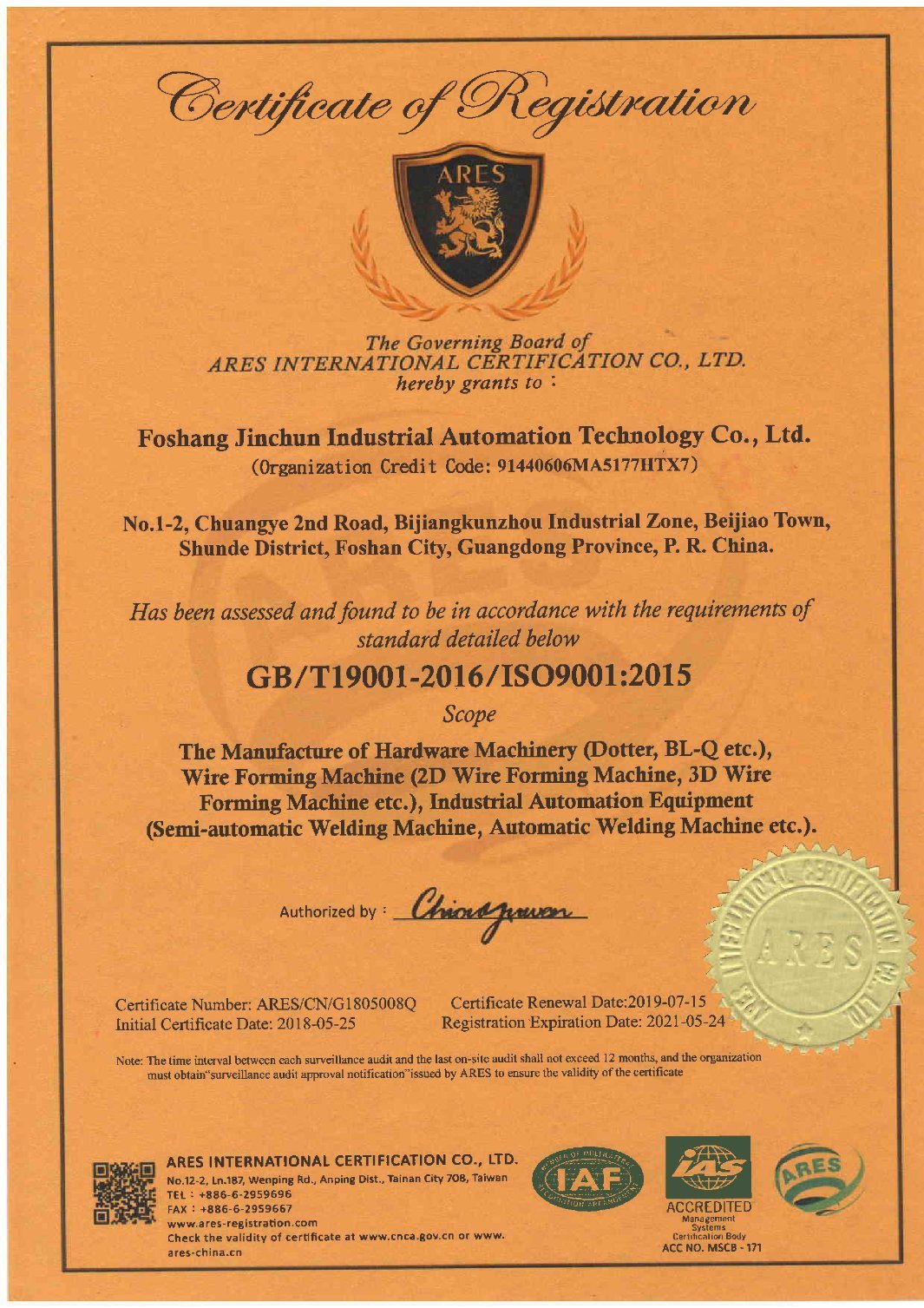

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

1. Who are we?

We are based in Guangdong, china, start from 1998,sell machine all over the world. There are total about 51-100 people inour office.

2.How can we guarantee quality?

Always a pre-production sample before mass production,

Always final Inspection before shipment;

3.What can you buy from us?

2D Wire bending machine, 3D wire bending machine,ring making butt welding machine,straightening machine,welding machine

4. Why should you buy from us not from other suppliers?

Efficient communication

Strong customization ability,.

Short lead time

Stable machine performance

Excellent after-sales service

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIFEXW;

Accepted Payment Currency:USD,EUR,HKD.CNY;

Accepted Payment Type: T/T,L/C,Credit card,Cash,

Language Spoken:English,Chinese

English

English Español

Español Português

Português русский

русский français

français