2D CNC Wire Bending Machine With PLC Control

2D CNC wire bending machine with PLC control enhances the performance and reliability of the machine.

Product Description

Introduction of 2D CNC Wire Bending Machine With PLC Control

What is a PLC control system? The PLC control system in a 2D CNC wire bending machine offers precise control and high reliability, enhancing production efficiency.

Product Specification of 2D CNC Wire Bending Machine With PLC Control

| Name | 2d cnc wire bending machine with PLC control |

| Electrical voltage | Three-phase 380V + ground wire |

| Number of straightening wheels | 22 groups |

| Applicable wire | round wire, flat wire, square wire (applicable to any material wire) |

| Wire feeding speed | fastest 25m/min |

| PLC | 32-bit high-performance processor |

| PLC language system | Chinese/English |

Feature and Application of 2D CNC Wire Bending Machine With PLC Control

The 2D CNC wire bending machine with PLC control system is a remarkable piece of equipment. The PLC provides accurate and efficient control, enabling precise bending of wires. It offers flexibility in programming different shapes and sizes. This machine is highly reliable and helps increase productivity in various industries. With its user-friendly interface and advanced control features, it simplifies the wire bending process and ensures consistent quality.efficacy,high quality, Advanced technology.

Instructions:

Operating the 2D CNC wire bending machine with PLC control system is straightforward. First, power on the machine and load the wire. Use the intuitive interface to input the desired bending parameters. The PLC control system precisely executes the commands, ensuring accurate bends. Monitor the process through the display. After completion, remove the bent wire. Regular maintenance includes cleaning and checking connections. With proper use, this machine offers reliable and efficient wire bending for various applications.

How To Use:

Instructions for Using 2D CNC Wire Bending Machine with PLC Control System Power On: Turn on the power switch of the machine. Wait for the system to initialize and the display to show the main interface. Wire Loading: Insert the wire into the appropriate feeding mechanism. Ensure the wire is properly aligned and secured. Programming: Use the user-friendly interface to input the specific bending parameters. This includes the angle, radius, and length of the bends. The PLC control system allows for precise programming and can store multiple programs for future use. Operation: Once the parameters are set, start the machine. The PLC control system will precisely control the bending process, ensuring accurate and consistent bends. Monitor the progress on the display. Adjustments: If necessary, make adjustments to the parameters during operation. The machine can be paused and resumed for fine-tuning. Completion: After the bending process is complete, carefully remove the bent wire. Inspect the product for quality and accuracy. Maintenance: Regularly clean the machine to remove dust and debris. Check the connections and components for any signs of wear or damage. Lubricate the moving parts as recommended by the manufacturer to ensure smooth operation. Safety Precautions: Always wear appropriate safety gear when operating the machine. Follow all safety instructions to prevent accidents and injuries.

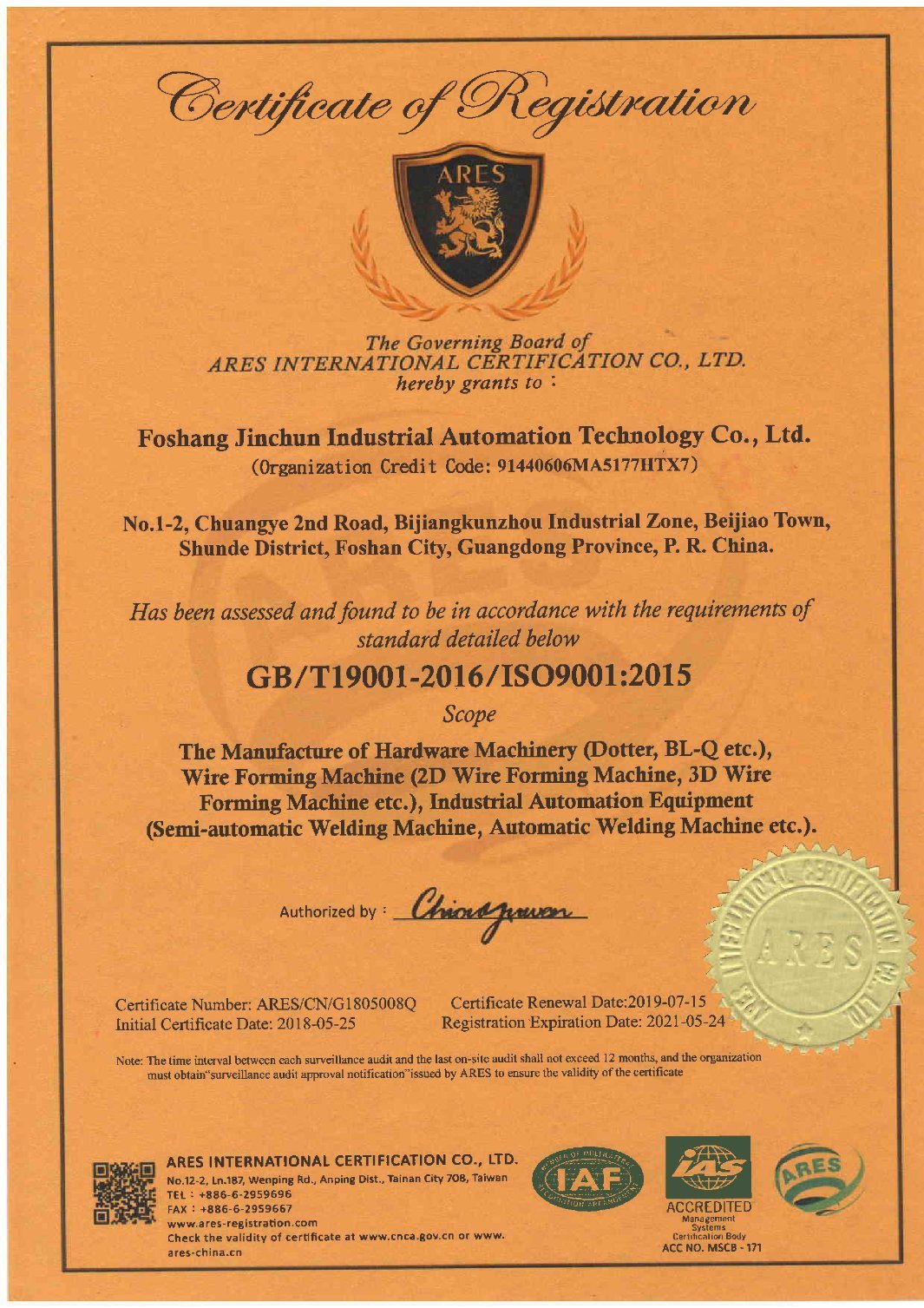

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français