High Precision Metal Bending Machines

High Precision metal bending machines offer exceptional accuracy and reliability. They can bend various metals with precision. Equipped with advanced technology, these machines are ideal for industries requiring intricate metalwork. They enhance productivity and quality in metal fabrication processes.

Product Description

Introduction of High Precision Metal Bending Machines

High Precision metal bending machines are advanced tools. They are designed to bend metals with utmost precision. Featuring state-of-the-art technology, they ensure consistent results. Widely used in manufacturing industries, these machines contribute to the production of high-quality metal products with complex shapes.

Product Specification of High Precision Metal Bending Machines

| Name | High Precision Metal Bending Machines |

| Electrical voltage | Three-phase 380V + ground wire |

| Number of straightening wheels | 22 groups |

| Applicable wire | round wire, flat wire, square wire (applicable to any material wire) |

| Wire feeding speed | fastest 25m/min |

| PLC | 32-bit high-performance processor |

| PLC language system | Chinese/English |

Feature and Application of High Precision Metal Bending Machines

High Precision metal bending machines have several important functions. They can bend metal sheets and bars with extreme accuracy, ensuring consistent angles and shapes. These machines are equipped with advanced controls for easy operation and customization. They find wide applications in various industries. In automotive manufacturing, they are used for producing body panels and frames. In construction, they help in making metal components for buildings. They are also essential in the production of appliances and machinery. With their high precision, they contribute to the quality and durability of metal products.

Instructions:

To use High Precision metal bending machines, first power on the device. Load the metal sheet or bar carefully. Set the desired bending parameters through the control panel, including angle and radius. Ensure all safety guards are in place. Start the machine and monitor the bending process. Once completed, carefully remove the bent metal. Regular maintenance is essential for optimal performance and longevity.

How To Use:

Power on the High Precision metal bending machine. Inspect the machine for any signs of damage or malfunction. Load the metal sheet or bar into the machine's clamping mechanism, ensuring it is securely held. Use the control panel to input the specific bending parameters such as angle, radius, and speed. Double-check the settings for accuracy. Start the machine and observe the bending process closely. If necessary, make adjustments during operation. After bending, carefully remove the metal piece. Clean and maintain the machine regularly to ensure its long-term performance.

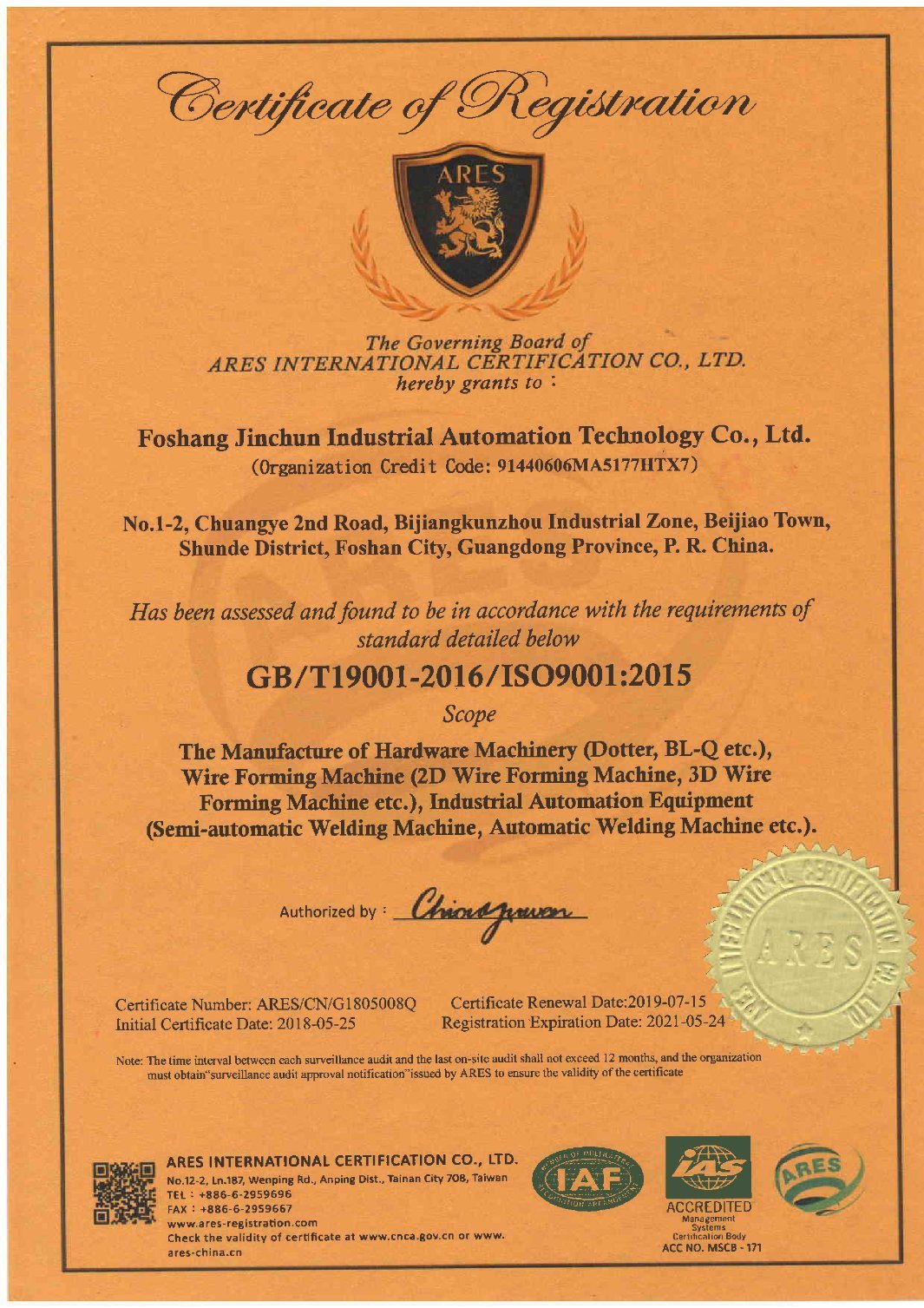

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

1. How can we guarantee quality?

We always provide videos of our machines making your samples.

2.What can you buy from us?

2D Wire bending machine, 3D wire bending machine, wire looping machine ,straightening machine, and welding machine.

3. Why should you buy from us not from other suppliers?

Our team have over 20 years of experience in R&D and manufacturing of hardware machinery and equipment.

4. What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, HKD, CNY;

Accepted Payment Type: T/T,L/C, Credit Card, Cash;

Language Spoken:English, Chinese

English

English Español

Español Português

Português русский

русский français

français