TIG Welding Foot Pedal

JINCHUN is a leading manufacturer and supplier of TIG welding foot pedals in the global market. We have been dedicated to welding equipment for many years. Our TIG welding foot pedals offer precise control over welding current, allowing for seamless welding operations. Crafted with high-quality materials, they are extremely durable and can endure various harsh working environments. The ergonomic design ensures comfort during long welding sessions, reducing fatigue.

Product Description

Introduction of TIG Welding Foot Pedal

Tig welding foot pedal is an essential accessory for achieving superior welds on stainless steel.

For one, it provides precise control over the welding process, enabling welders to adjust the heat input and current with ease. This is crucial for stainless steel as it requires careful temperature management to avoid overheating and distortion.

Moreover, the foot pedal allows for smooth and consistent welding, resulting in high-quality welds with minimal defects. Stainless steel demands clean and uniform welds to maintain its corrosion resistance and aesthetic appeal.

Product Specification of TIG Welding Foot Pedal

| Name | Tig welding foot pedal |

| Power and voltage | 380V 50HZ |

| Weight | 280kg |

| Welding workpiece | Iron wire and stainless wire |

| Applicable wire |

Stainless steel,normal carbon steel wire |

| Rate power |

customize |

| Max electrode par distance |

60(mm) |

Feature And Application of TIG Welding Foot Pedal

Feature:

I. High welding quality

Since argon arc welding can effectively protect the molten pool during the welding process and prevent adverse effects of oxygen, nitrogen, and other substances in the air on the weld, the welded stainless steel has good corrosion resistance and can be used for a long time in various harsh environments.

II. Clean and environmentally friendly

1. No harmful substances are generated during the welding process: Argon arc welding does not produce harmful smoke, dust, and other substances during the welding process, having little impact on the environment and the health of operators.

2.The weld seam does not require subsequent treatment: Due to the high quality of the weld seam of argon arc welding, usually no subsequent grinding, polishing, and other treatments are required, reducing processing procedures and environmental pollution.

Application:

Instructions:

Operation process

1. Hold the TIG welding torch in your hand and align the tungsten electrode of the welding torch with the welding position. Before starting welding, ensure that the welding position is clean and free of oil and impurities to ensure welding quality.

2. Place your foot gently on the foot pedal controller and feel the pressure feedback of the foot pedal controller. During the welding process, control the welding current by adjusting the pressure of your foot on the foot pedal controller.

3. When it is time to start welding, gradually increase the pressure of your foot on the foot pedal controller. As the pressure increases, the welding current will also gradually increase. Adjust to the appropriate welding current according to the requirements of the welding process and start welding.

4. During the welding process, you can adjust the pressure of your foot on the foot pedal controller at any time as needed to control the welding current. If you need to reduce the welding current, gradually reduce the pressure of your foot on the foot pedal controller. If you need to increase the welding current, gradually increase the pressure of your foot on the foot pedal controller.

5. When the welding is completed, remove your foot from the foot pedal controller, and the welding current will gradually decrease to zero. At this time, you can turn off the power of the welding equipment and complete the welding operation.

Precautions:

According to the requirements of the welding process and your own welding experience, reasonably adjust the sensitivity of the foot pedal controller and the size of the welding current. If the sensitivity is too high or the welding current is too large, it may cause problems such as overheating and burn-through of the welding; if the sensitivity is too low or the welding current is too small, it may cause problems such as weak welding and poor weld quality.

During the welding process, pay attention to observing the situation of the welding position and adjust the welding current and welding speed in time to ensure welding quality. If abnormal conditions such as pores and cracks are found in the welding position, stop welding immediately, check the welding equipment and welding process, find out the problem and deal with it.

When using the foot pedal controller, pay attention to safety. Avoid getting your foot caught or injured by the foot pedal controller. At the same time, follow the welding safety operation procedures and wear personal protective equipment such as welding gloves and goggles.

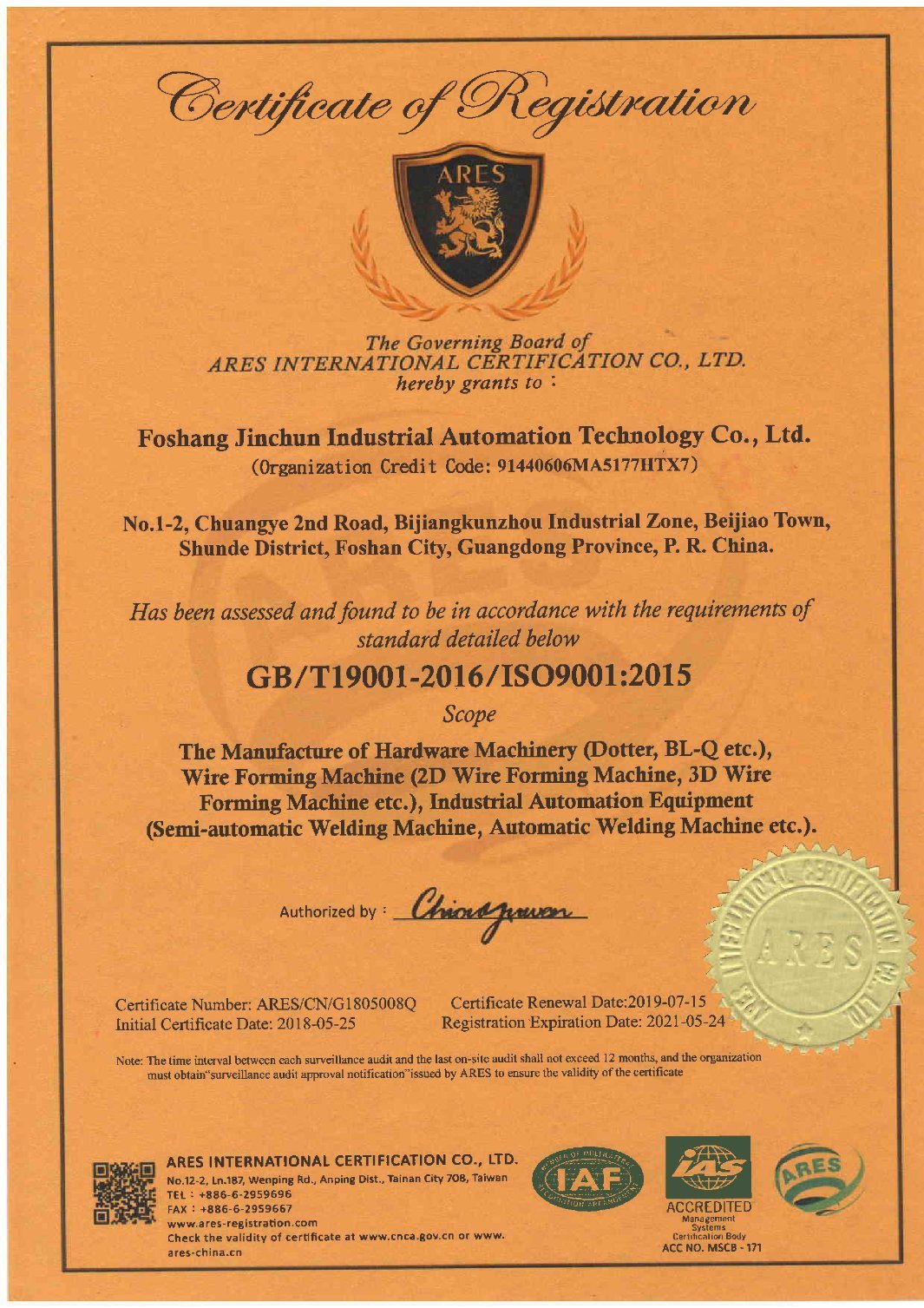

Product Qualification

|

|

Deliver, Shipping And Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français