Servo Motor Straightening Cutting Machine

The full-servo motor is a high-performance motor type. It adopts advanced servo control technology and can achieve precise position, speed and torque control.

Product Description

Straightening and cutting machine

Introduction of Servo Motor Straightening Cutting Machine

The full-servo motor usually consists of a motor body, an encoder and a driver. The encoder provides real-time feedback of the position and speed information of the motor, and the driver precisely controls the motor according to the control instructions and feedback information.

Product Specifications of Servo Motor Straightening Cutting Machine

| Name | Servo cut wire straightening and cutting machine |

| Model | no. 2-6 / 3-8 |

| Cutting length range | 50mm-unlimited |

| Wire feeding speed Adjustable speed | 7-35m/min |

| Applicable wire | Stainless steel,normal carbon steel wire |

| Cutting motor | 1KW / 2.2KW |

| Machine dimension(L*W*H) | 2460*710*1450(mm) |

Feature and Application Servo Motor Straightening Cutting Machine

1. High-precision control: It can achieve very precise position, speed and torque control to meet the needs of high-precision processing and motion control.

2. Fast response: It has a fast response speed and can quickly follow the changes of control instructions to achieve fast dynamic response.

3. High reliability: It has good reliability and stability and can operate stably for a long time in harsh working environments.

4.Energy-saving and high efficiency: It has high efficiency and can reduce energy consumption while achieving high performance.

Application:all kinds of wire rods straightening and cutting

Instructions:

Put the wire that needs to be straightened into the feed inlet. Note that the diameter of the wire should be within the applicable range of the equipment.

Adjust the feeding speed to avoid being too fast or too slow so as not to affect the straightening effect.

Straightening process:

The wire is straightened by passing through the straightening wheels. Adjust the pressure and spacing of the straightening wheels according to the actual situation of the wire.

Cutting operation:

When the wire reaches the required length, start the cutting device to cut the wire.

When adjusting the cutting length, it can be set through the control system of the equipment.

Shutdown operation:

After the work is completed, first turn off the cutting device and then stop the motor.

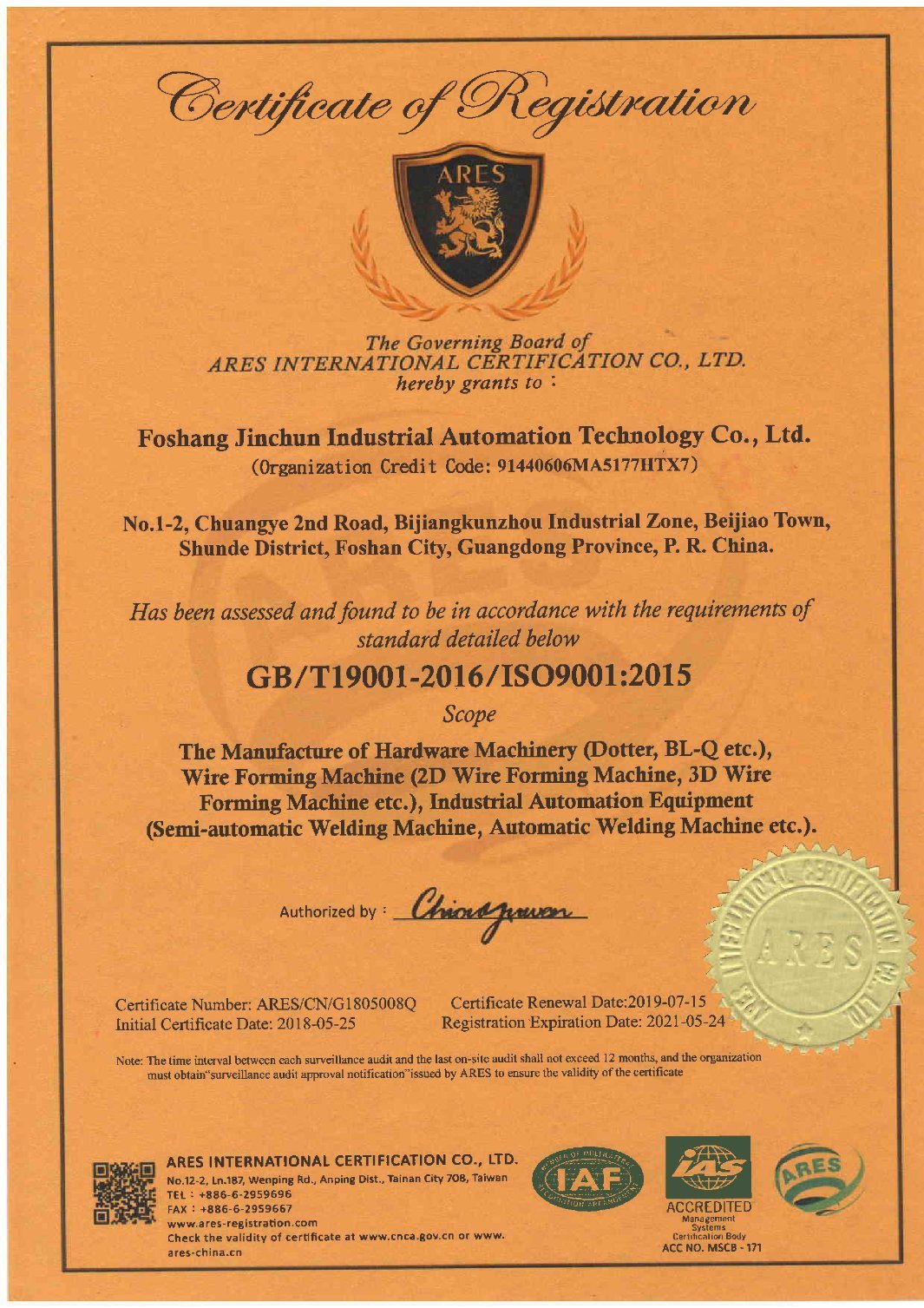

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français