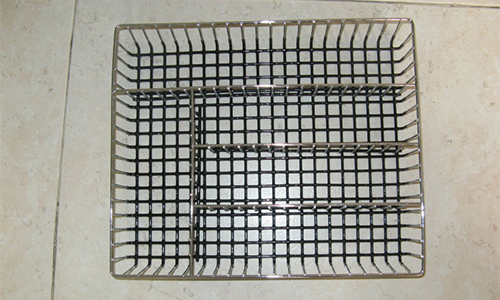

Automatic 2D CNC Flat Wire Bending Machine With Welding

The Automatic 2D CNC Flat Wire Bending Machine With Welding combines bending and welding functions. It offers precise control and high efficiency. Ideal for various industries, it simplifies production processes and improves product quality.

Product Description

Introduction of Automatic 2D CNC Flat Wire Bending Machine With Welding

The Automatic 2D CNC Flat Wire Bending Machine with Welding is a high-tech device. It can precisely bend flat wires and perform welding. With CNC control, it ensures accuracy and efficiency. Widely used in industries, it streamlines production and delivers quality products.

|

|

Product Specification of Automatic 2D CNC Flat Wire Bending Machine With Welding

| Name | Automatic 2D CNC Flat Wire Bending Machine With Welding |

| Electrical voltage | Three-phase 380V + ground wire |

| Number of straightening wheels | 28 groups |

| Machine weight | 850KG |

| Bending precision | ±0.5 ° |

| Wire Feeding Precision | ±0.5 ° |

| Applicable wire | Round wire, flat wire, square wire |

Feature and Application of Automatic 2D CNC Flat Wire Bending Machine With Welding

The clothes bender machine has several important functions. It can quickly and neatly bend clothes of various sizes. This helps in saving storage space and keeping closets organized. It is widely used in households, laundry services, and clothing stores. It simplifies the process of handling clothes and makes them easier to stack and store. With its efficient design, it is a valuable tool for anyone dealing with large amounts of clothing.

Instructions:

Instructions for Automatic 2D CNC Flat Wire Bending Machine with Welding: First, load the flat wire. Set the parameters via the control panel. Start the machine. It will bend and weld the wire accurately. Monitor the process. After use, clean and maintain the machine for optimal performance. Ensure safety during operation.

How To Use:

Instructions for Automatic 2D CNC Flat Wire Bending Machine with Welding: 1. Preparation - Inspect the machine for any damage and ensure all connections are secure. - Prepare the flat wire of appropriate size and quality. 2. Loading - Place the flat wire on the feeding mechanism carefully. 3. Parameter Setting - Use the control panel to set bending angles, welding parameters, and other specifications according to your requirements. 4. Operation - Start the machine. The CNC system will control the bending and welding processes accurately. - Monitor the operation closely to ensure smooth progress. 5. Post-Operation - Inspect the finished product for quality. - Clean and maintain the machine regularly for optimal performance and longevity. Always follow safety guidelines when operating the machine.

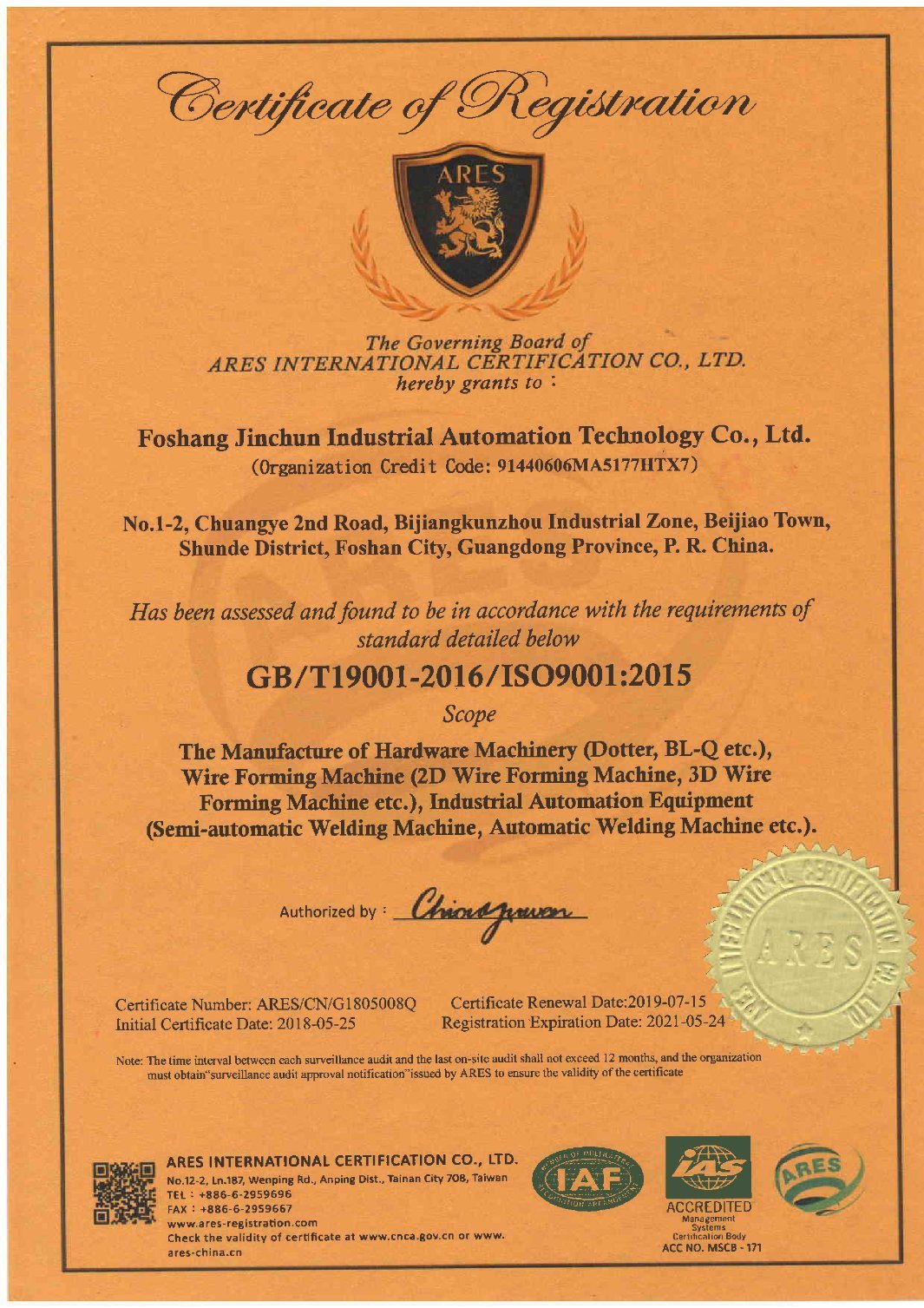

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français