2D CNC Flat Wire Square Bending With Hole Punching Machine

The 2D CNC Flat Wire Square Bending with Hole Punching Machine is a high-tech device. It can bend flat wire into squares and punch holes. Offers precision and efficiency. Ideal for wire processing industries, enhancing productivity and product quality.

Product Description

Introduction of 2D CNC Flat Wire Square Bending With Hole Punching Machine

The 2D CNC Flat Wire Square Bending with Hole Punching Machine is a versatile tool. It can precisely bend flat wire into squares and punch holes. With CNC control, it ensures accuracy and efficiency. Widely used in wire processing, it simplifies production and delivers high-quality products.

Product Specification of 2D CNC Flat Wire Square Bending With Hole Punching Machine

| Name | 2D CNC Flat Wire Square Bending With Hole Punching Machine |

| Electrical voltage | Three-phase 380V + ground wire |

| Number of straightening wheels | 28 groups |

| Machine weight | 850KG |

| Bending precision | ±0.5 ° |

| Wire Feeding Precision | ±0.5 ° |

| Applicable wire | Round wire, flat wire, square wire |

Feature and Application of 2D CNC Flat Wire Square Bending With Hole Punching Machine

The 2D CNC Flat Wire Square Bending with Hole Punching Machine has multiple functions. It can accurately bend flat wire into square shapes and punch holes at specific locations. This machine is widely used in industries such as electronics, furniture, and automotive. It helps in creating wire frames and components with precision, improving production efficiency and product quality.

Instructions:

Instructions for 2D CNC Flat Wire Square Bending with Hole Punching Machine: First, load the flat wire. Set the parameters on the CNC control panel for bending and hole punching. Start the machine. It will perform the operations accurately. Monitor the process. After use, clean and maintain the machine. Ensure safety during operation. Follow these steps for optimal results.

How To Use:

Instructions for 2D CNC Flat Wire Square Bending with Hole Punching Machine: Load flat wire properly. Use the control panel to input desired bending angles and hole positions. Start the machine. It will bend and punch accurately. Monitor the process for any issues. After use, clean and maintain. Ensure safety precautions are followed. Operate with care for best results.

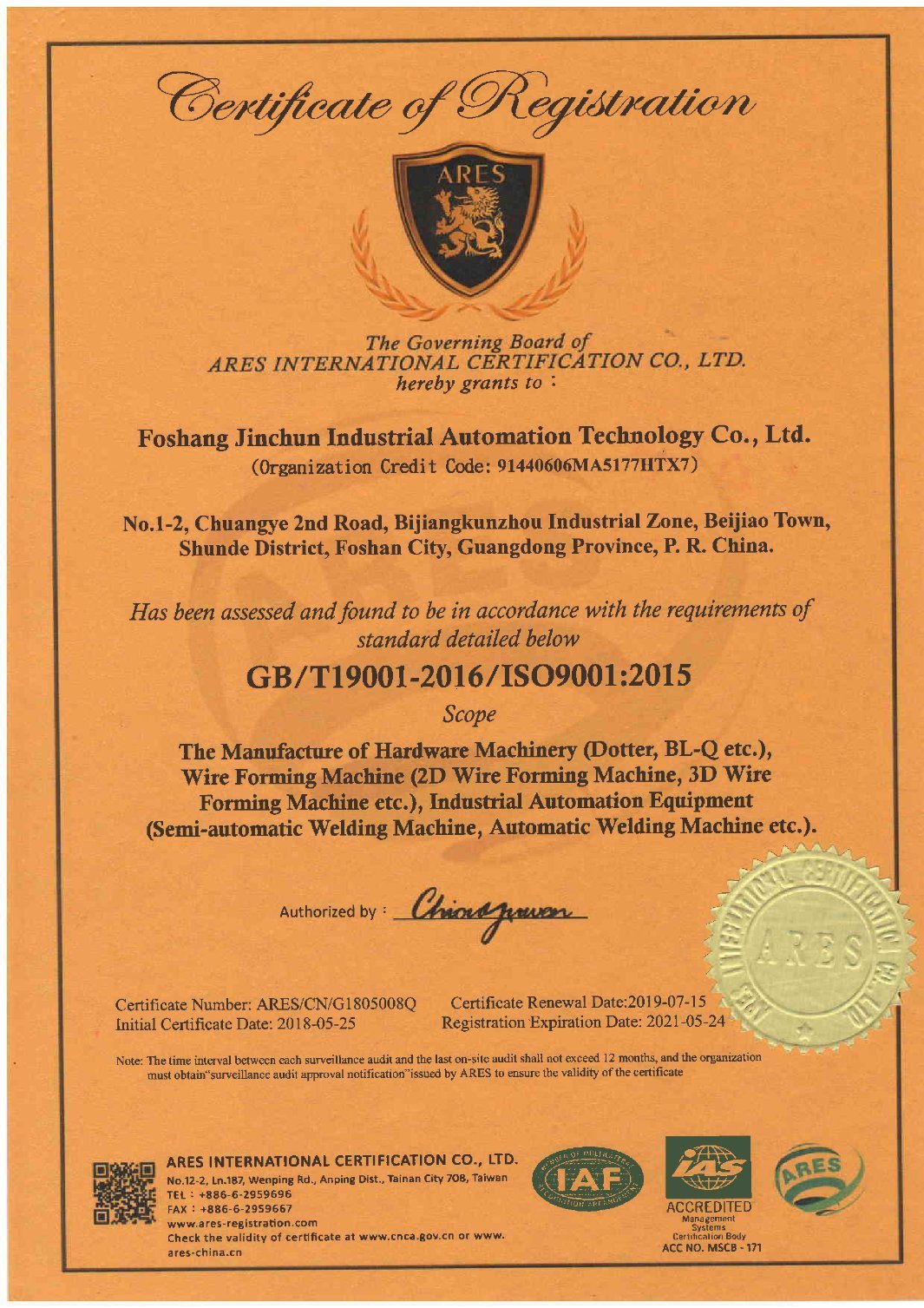

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements.

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation.

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français