Ring Making Machine

A ring-making machine, also known as a coiling machine or winding machine, is a mechanical device used for processing metal wire materials (such as steel wire, copper wire, aluminum wire, etc.) into circular, square, or other shaped ring products. This equipment is widely used in various industrial fields.

Product Description

Introduction of Ring Making Machine

Why is Jinchun's ring-making machine popular?

As the product that made Jinchun Company prosperous, why has the ring-making machine remained popular for over 30 years, with a large number of domestic and international customers continuously purchasing it for manufacturing flanges, iron artworks, pot racks, and other metal wire products?

Product Specifications of Ring Making Machine

| Name | 2-10 Ring making mahcine |

| Power supply | 3 phases 380V |

| Cutter cylinder cutting force | 80 |

| Ring rang | 80-800 |

| Available wire material | Round wire / flat wire/ square wire |

| Feeding wire wheels sets | 3 |

| Machine size | 1750*7801450 |

Feature of Ring Making Machine

The looping machine of Jinchun Company is widely welcomed in the market due to its multiple unique technical advantages:

High precision and high speed: The looping machine of Jinchun can achieve high-speed and high-precision processing, with an error controlled below 0.5mm. Some models can even select imported encoders to improve stability and precision.

Versatility: The machine can adjust the cutting knife for straight line and arc processing, as well as the production of single circle, double circle and spring functions.

Easy operation: The parameter setting is intuitive, the operation is simple and convenient, and it is equipped with multiple function control modes such as manual, automatic and test run.

Energy-saving design: The looping machine adopts energy-saving control. If there is no operation for three minutes, the main motor will automatically stop to save energy.

Power failure memory function: In case of power failure, it can remember the set parameters without repeated setting to ensure the continuity of production.

Professional design: Directly driven by hydraulic motor, without gear assistance, reducing gear clearance and improving accuracy.

Stability: The wire feeding is stable, fast and accurate. It has forward and reverse functions and is easy to adjust.

High-quality components: The professionally designed and manufactured hydraulic power station. The electromagnetic oil valve, oil pump and oil pump motor are Taiwanese products to ensure stable oil pressure.

Counting function: It has a counting function. The production output can be set. It will automatically stop after finishing, improving production efficiency.

Imported encoder: Some models use imported encoders to ensure the accuracy of measurement.

Cooling system: It is equipped with a water passage device to keep the oil temperature stable, avoid excessive oil temperature due to long-term work, and ensure processing accuracy.

Control system: It is controlled by a single-chip microcomputer program. The main parts use imported components to ensure the high precision and stability of the machine and prolong the service life.

These technical advantages make Jinchun's looping machine perform outstandingly in manufacturing metal wire products such as flanges, iron art and pot racks, meeting diverse industrial needs.

Instructions:

Wire feeding: The metal wire is fed into the machine.

Wire straightening: The wire is straightened during the feeding process to ensure the precision of the processing.

Wire forming: The wire is bent into the required shape through molds or forming mechanisms.

Cutting : The formed wire is cut to the appropriate length。Finished product collection: The completed ring products are collected for subsequent processing or packaging.

Application:

1:Metal furniture manufacturing: For producing legs, brackets, and other parts of metal furniture.

2:Construction industry: For making various metal rings and hoops used in construction.

3:Hardware products: For manufacturing ring components in hardware tools and accessories.

4:Automotive manufacturing: For creating ring parts in automotive components.

5:Crafts manufacturing: For making decorative metal rings and other ornaments.

6:Iron art production: For fabricating decorative and structural rings in iron art doors, windows, railings, etc.

7:Kitchenware: For producing pot racks, stove racks, and other kitchen utensils.

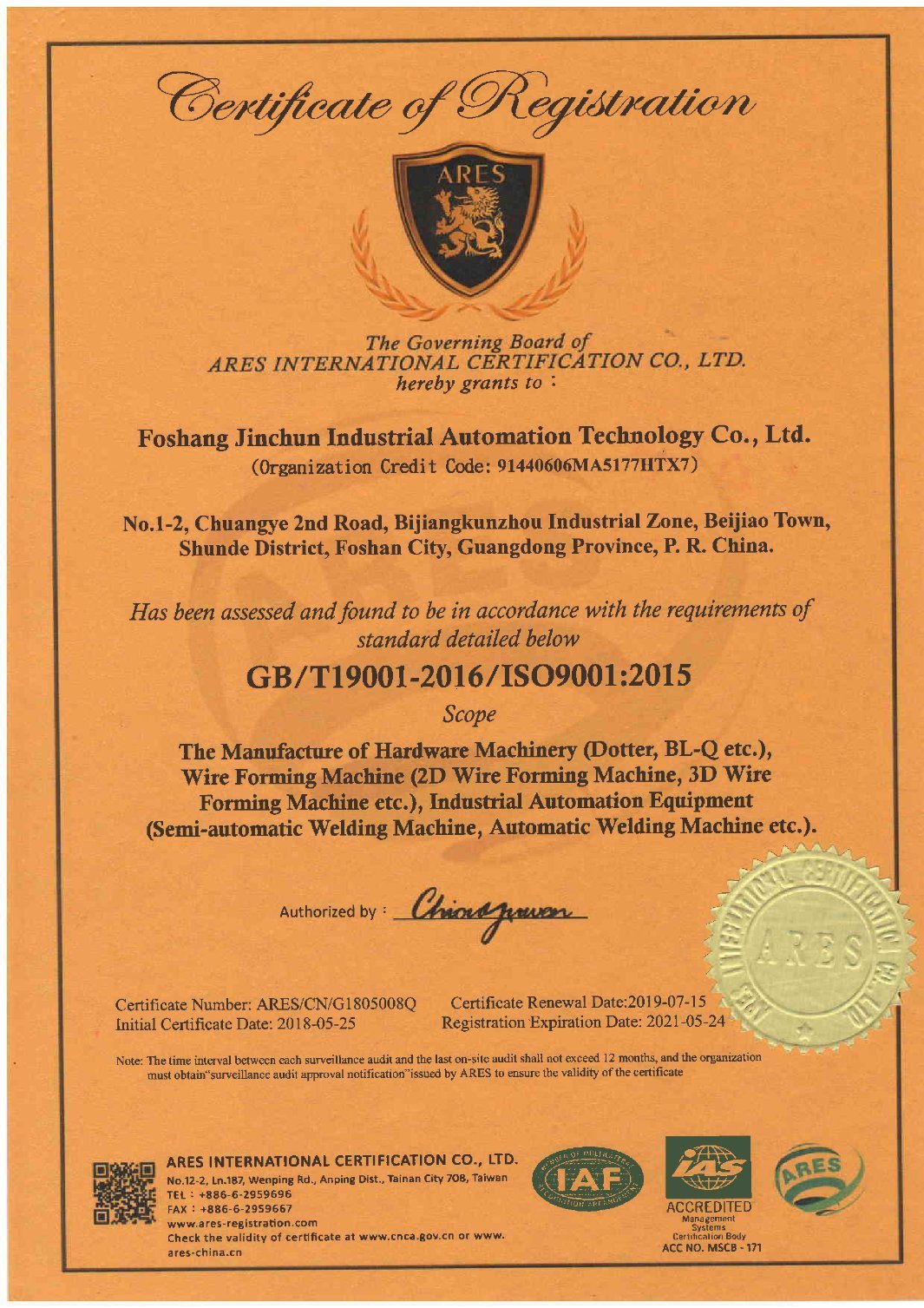

Product Qualification

|

|

Deliver, Shipping And Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français