Gantry Welding Machine

The gantry welding machine in the fully automatic welding machine can greatly improve the efficiency of making mesh products.

Product Description

Welding Machine

Introduction of customizes welding equipment - The gantry welding machine

Gantry welding machine is a large welding equipment,Structural characteristics It usually has a gantry-like frame structure, which is sturdy and stable. This structural design enables it to span a large working area and adapt to the welding needs of workpieces of different sizes.

Product Specifications of Gantry Welding Machine

| Name | Gantry Welding Machine |

| Electrical voltage | 3-phase AC380V ±10% |

| Working pressure | 0.5~0.7MPA (customizes) |

| Welding power source | AC power (customizes) |

| Control screen | Touch screen (customizes) |

| Welding process | Row welding (customizes) |

| Clamp moving speed | Forward 500 mm/s (customizes) |

Feature and Application of Gantry Welding Machine

1. Sturdy Structure: The gantry welding machine has a frame structure similar to a gantry. This design gives it extremely high stability and is able to withstand the stress generated during the welding of large workpieces.

2. Large Working Area: It can span a relatively large working area and meet the welding needs of workpieces of different sizes. Both small components and large metal structural parts can be welded.

3. High-Precision Welding: Through an advanced control system, high-precision welding can be achieved, ensuring the quality and dimensional accuracy of weld seams and making the welded parts firm and reliable.

4. Efficient Welding: It can perform welding of multiple weld seams simultaneously or continuous welding of large workpieces, greatly improving welding efficiency and saving production time and cost.

5. High Degree of Automation: According to the preset welding program, the welding gun or welding device is driven to move and position accurately in the directions of the crossbeam and column of the gantry frame, realizing automated welding operations, reducing manual intervention and improving the consistency of welding quality.

Application:Weld mechanical parts, especially welded mesh surface and mesh products.

Instructions:

The gantry welding machine drives the welding gun or welding device to move and position accurately in the direction of the crossbeam and column of the gantry frame through an advanced control system. According to the preset welding program, automated welding operations can be performed on the workpiece.

How To Use:

1. Turn on the equipment: Press the power switch of the gantry welding machine to start the equipment.

2. Adjust the position of the welding gun: Through the control system, adjust the position of the welding gun to align it with the part to be welded. Manual or automatic adjustment methods can be used to ensure that the position of the welding gun is accurate.

3. Set the welding program: According to the welding requirements, set the welding program. You can choose automatic welding mode or manual welding mode. In automatic welding mode, the equipment will perform welding operations according to the preset program; in manual welding mode

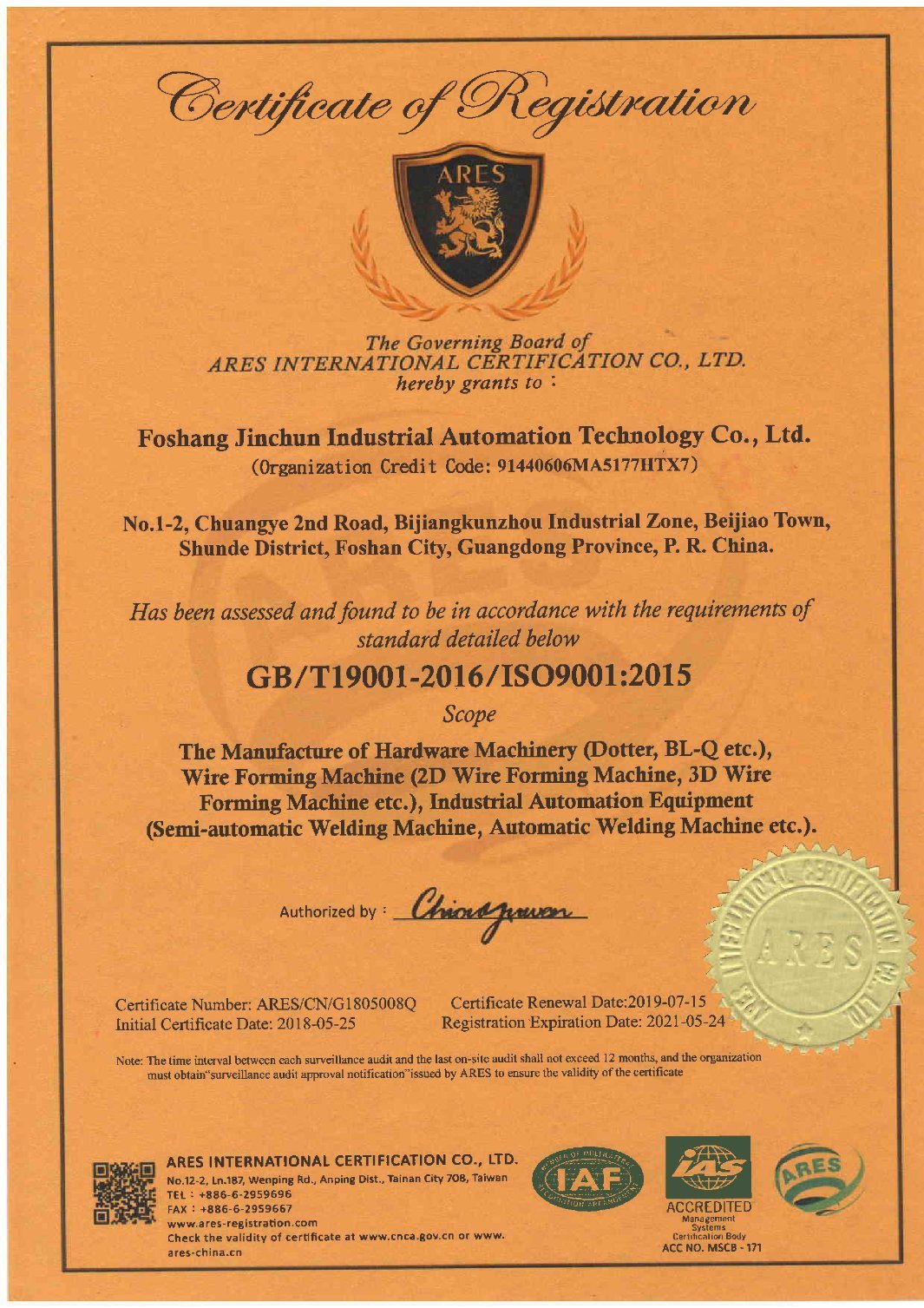

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français