Fixed-Cut Wire Straightening and Cutting Machine

Jinchun High Quality 2-6mm Automatic Straightening Cutting Machine Engineers Fixed-Cut Metal Steel Wire Straightener Motor Core

Product Description

Product Overview

The fixed type wire straightening machine has the characteristics of reasonable structure, convenient operation, safety andreliability, fast speed, a small error, and no wire running. it is suitable for the straightening of chicken cages, rabbitcages, net covers, pet cages, construction nets, various welding wires, Shule plate wire cutting, and wires forspecial-shaped nets.

SPECIFICATIONS

| Straightening Machine with Fixed Cut | |

| wire diameter | Φ2-6mm |

| Machine power | 5.5KW |

| wire diameter | 2-6mm iron wire |

| feeding servo motor | 2KW |

| cutting servo motor | 1kw |

| straightening servo motro | 3kw |

Key Technical Parameters:

With its adjustable settings, operators can easily program the machine to cut metal coils into desired lengths with high accuracy and consistency. The straightening unit helps to flatten and remove any imperfections in the metal strips, resulting in smooth and even surfaces.

The precision cut-to-length and straightening machine is essential for manufacturers looking to increase efficiency and productivity in metal processing operations. Its reliable performance, user-friendly interface, and advanced control system make it a valuable asset for businesses seeking to improve the quality of their products and streamline their production processes.

Accuracy plus or minus 0.5mm, can cut the shortest 3mm, the longest unlimited wire. More accurate cutting, automatic tracking of straightening speed to automatically compensate straightening loss wear.

Wire straightening and cutting machines for iron wire come in various sizes and capacities, ranging from small tabletop machines for low-volume production to large automated machines for high-volume production. They can handle different types of iron wires, including mild steel wire, stainless steel wire, and galvanized wire, with varying diameters and lengths.

These Wire straightening and cutting machines are commonly used in applications where straight and accurately cut wire is required, such as in the production of wire mesh, wire ropes, wire hangers, and reinforcement bars for concrete structures. They are efficient, precise, and labor-saving, helping to improve productivity and reduce production costs in wire processing operations.

What product shapes are compatible with this machine?

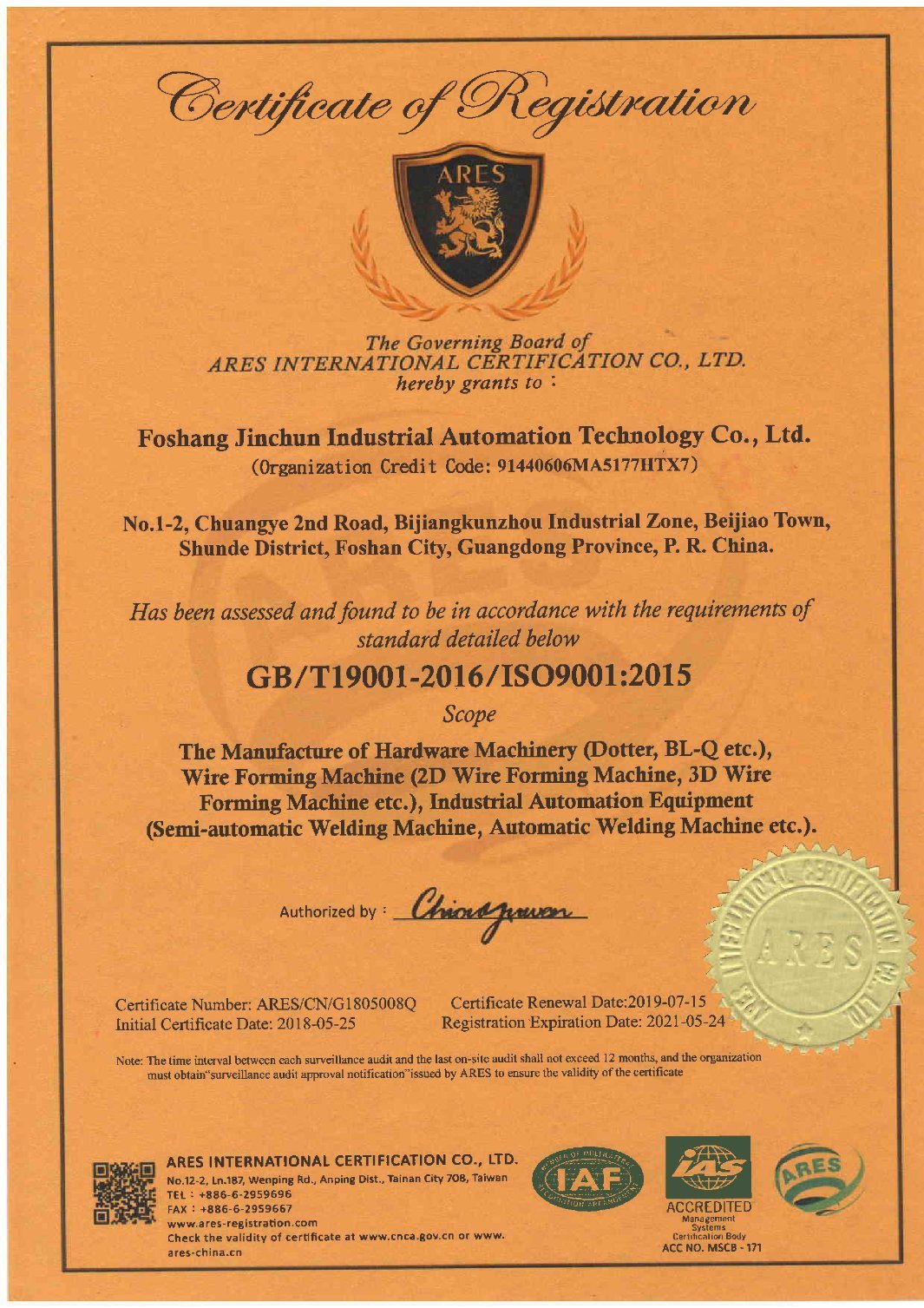

Product Qualification

|

|

Deliver, Shipping And Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1: What is the price of your machine?

A. our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

The material and thickness of your product

The minimum and maximum size of your product

The welding position of your products

The automation level that you want to achieve

It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical proposal and price for you.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What is the delivery time of your machine?

A. it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français