CNC 3D Bending For Furniture And Chairs Use

CNC 3D bending for Furniture and Chairs. Precise bending for customized designs. Streamlines production. Enhances aesthetics. Ideal for creating unique furniture pieces with durability and style.

Product Description

Introduction of CNC 3D Bending For Furniture And Chairs Use

CNC 3D bending for Furniture and Chairs offers precise shaping. It can create complex forms for unique furniture designs. With advanced technology, it ensures high quality and efficiency. Ideal for manufacturers seeking innovative solutions for furniture production.

Product Specification of CNC 3D Bending For Furniture And Chairs Use

| Name | CNC 3D Bending For Furniture And Chairs Use |

| Wire diameter range | 8-16mm |

| length * width *height | 3900*1450*1750 |

| Total Weight | 3200KG |

| CNC axis quantity | 5-axis |

| Operating Voltage | 380V to 220V |

| Corner accuracy | 90 degrees plus or minus 0.1 |

| Wire feeding accuracy | 300MM plus or minus 0.1 |

| Maximum wire feeding speed | 110 m/min |

Feature and Application of CNC 3D Bending For Furniture And Chairs Use

The CNC 3D bending for Furniture and Chairs can shape materials in three dimensions with high precision. It is used to create unique furniture designs. Ideal for both mass production and custom-made pieces. Enhances the aesthetics and functionality of furniture.

Application:Pet cage, fruit rack, flower rack, barbecue net cover, hook, drying rack, stainless steel storage rack

Instructions:

Instructions for CNC 3D bending for Furniture and Chairs: Load the material. Set the 3D bending parameters. Start the machine. Monitor the process. After use, clean and maintain. Ideal for creating unique furniture and chair designs with precision and efficiency.

How To Use:

Instructions for CNC 3D Bending for Furniture and Chairs:

Preparation: Inspect the machine for any damage or malfunctions. Ensure proper power supply and connection.

Loading Material: Carefully place the material to be bent into the machine's work area. Make sure it is properly secured.

Setting Parameters: Use the control panel to input the desired 3D bending specifications, such as angles, curves, and dimensions.

Operation: Start the machine and monitor the bending process closely. Adjust parameters if needed for optimal results.

Completion: Once the bending is complete, turn off the machine and remove the finished piece.

Maintenance: Regularly clean the machine and check for wear and tear. Perform routine maintenance as per the manufacturer's instructions to ensure long-term performance.

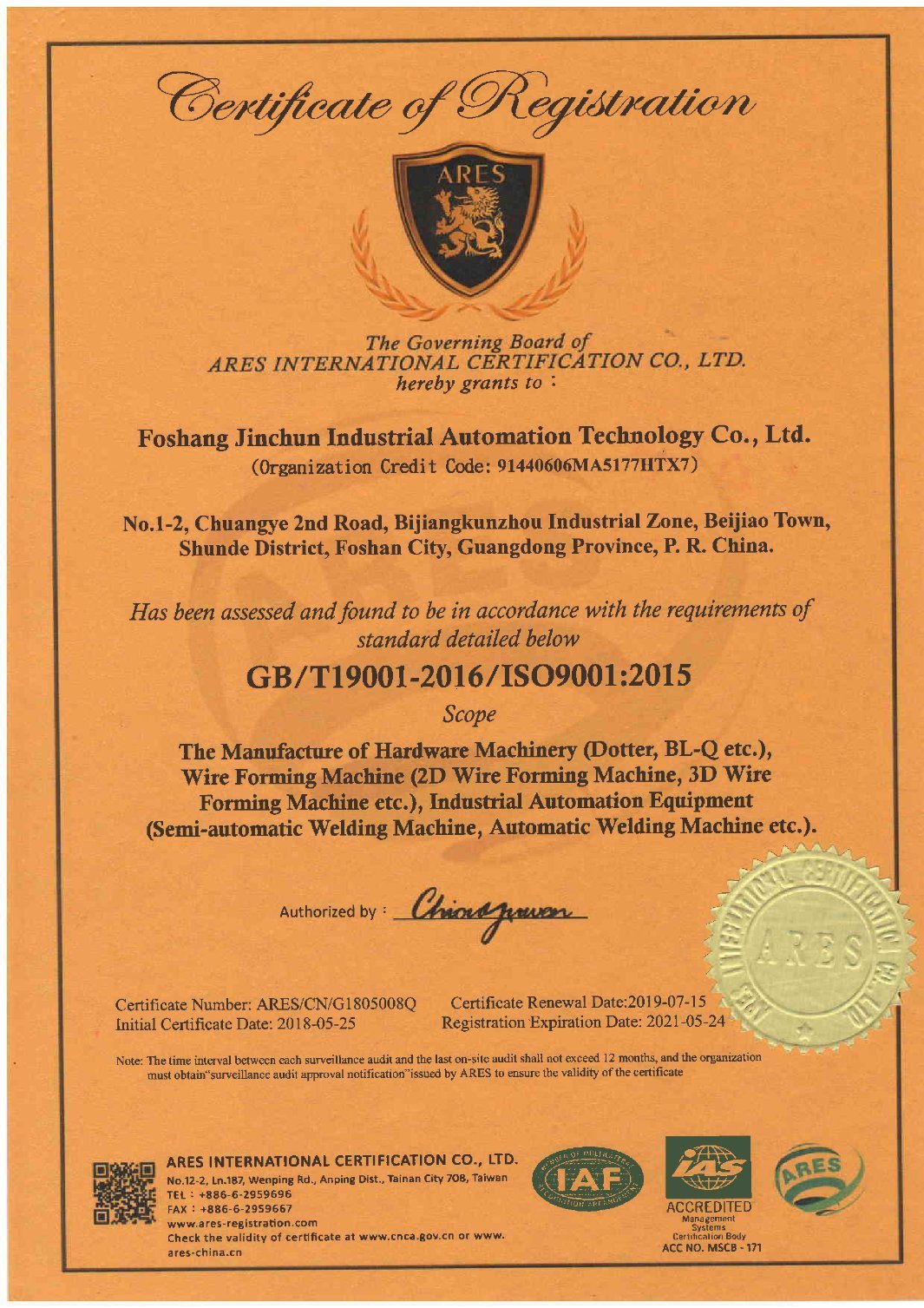

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français