Iron Wire Hanger Making Machine

The Wire Bending Machine with Chamfering offers precise wire bending and chamfering. It enhances product quality and safety. Ideal for various industries. Efficient and reliable.

Product Description

Wire Ring Making Machine

Introduction of Iron Wire Hanger Making Machine

The Wire Bending Machine with Chamfering is a versatile tool. It bends wires accurately and adds chamfering for smooth edges. Ideal for different applications. Ensures high-quality wire products with its advanced features and functionality.

Product Specification of Iron Wire Hanger Making Machine

| Name | Iron Wire Hanger Making Machine |

| Electrical voltage | 3Phases 4 wires+ground wire |

| Model No./Wire diameter | 2-6 / 3-8 / 5-10 / 6-12 |

| Chamfering | Chamering motor power:1.5KW |

| Function:Lifing,rotating and chamfering | |

| Separate start and stop operation | |

| Chamfering range:Adjust the chamfering knife position to realize chamfering effect |

Feature and Application of Iron Wire Hanger Making Machine

The Wire Bending Machine with Chamfering can bend wires precisely into various shapes. The chamfering function creates smooth edges, reducing the risk of injury. It is efficient and easy to operate. With advanced technology, it offers high accuracy and reliability. Ideal for different industries.

Application:Exquisite iron crafts, air oven racks, steamer racks, flower racks, chicken cages

Instructions:

Instructions for Wire Bending Machine with Chamfering: Load the wire. Set the bending and chamfering parameters. Start the machine. Monitor the process. After use, clean and maintain. Ideal for accurate wire bending and chamfering in various applications. Ensures high quality results.

How To Use:

Wire Bending Machine with Chamfering Operation Guide:

Preparation:

1.Inspect the machine to ensure it is in good working condition and all parts are securely attached.

2.Check the power supply and make sure it is properly connected.

Loading the Wire:

1.Select the appropriate wire size and material for your intended application.

2.Insert the wire into the loading mechanism of the machine, ensuring it is properly aligned and seated.

Setting Bending Parameters:

1.Use the control panel to set the desired bending angles and dimensions.

2.Adjust the speed and pressure settings according to the wire material and thickness.

Chamfering Settings:

1.If chamfering is required, select the appropriate chamfering tool and set the chamfering depth and angle.

2.Ensure the chamfering tool is properly installed and aligned.

Operation:

1.Start the machine and carefully monitor the bending and chamfering process.

2. Make any necessary adjustments to the settings during operation to ensure accurate results.

3. Keep hands and other body parts away from the moving parts of the machine to prevent injury.

Completion:

1.Once the wire has been bent and chamfered to the desired specifications, stop the machine.

2.Remove the finished product from the machine carefully.

3.Clean the machine after use to remove any debris or wire fragments.

Maintenance:

1.Regularly inspect the machine for wear and tear and replace any damaged parts promptly.

2.Lubricate the moving parts of the machine as recommended by the manufacturer.

3. Keep the machine in a clean and dry environment to prevent corrosion and damage.

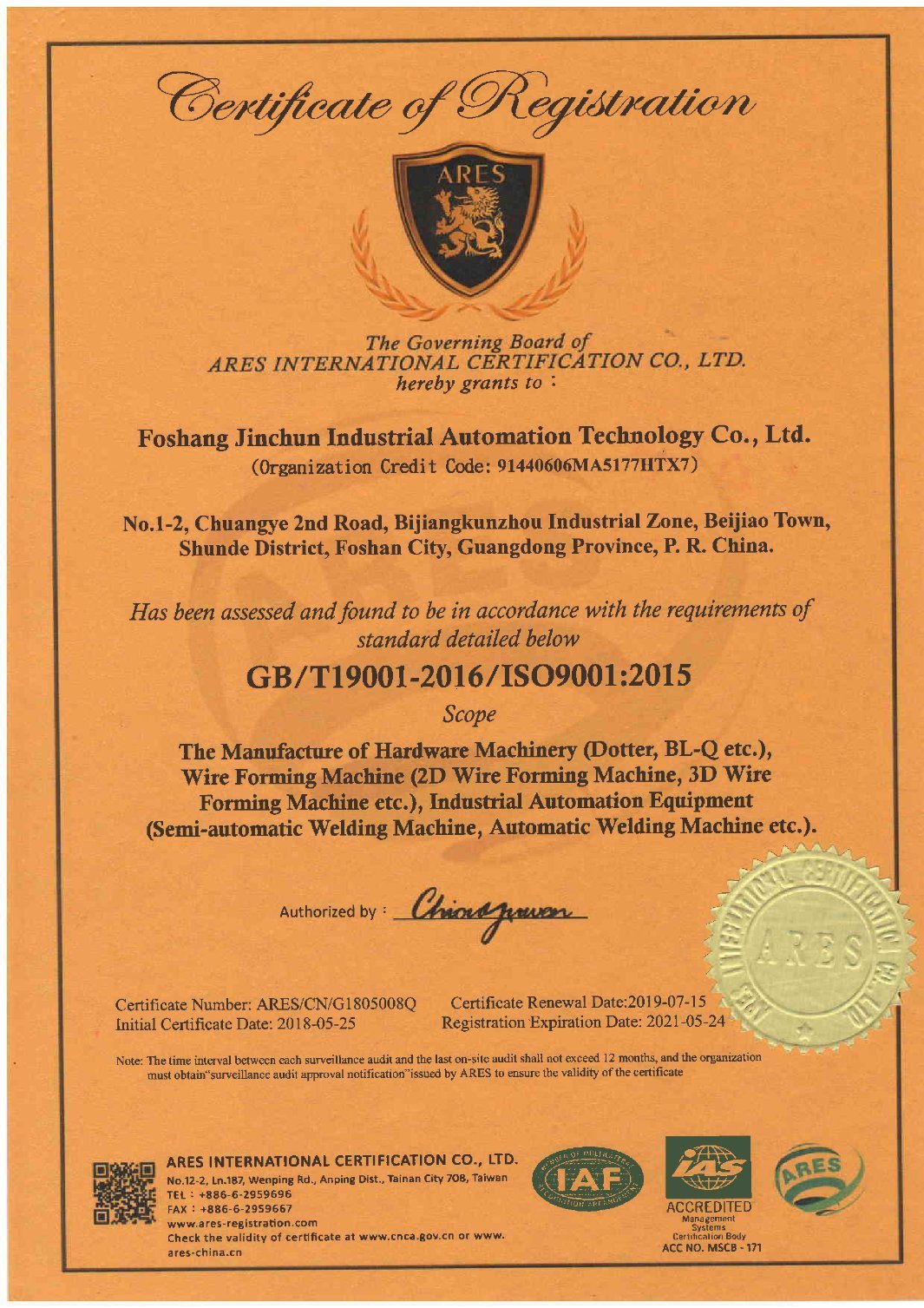

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.

English

English Español

Español Português

Português русский

русский français

français